New Strategy to Reduce Tissue Damage from Flesh-eating Bacteria

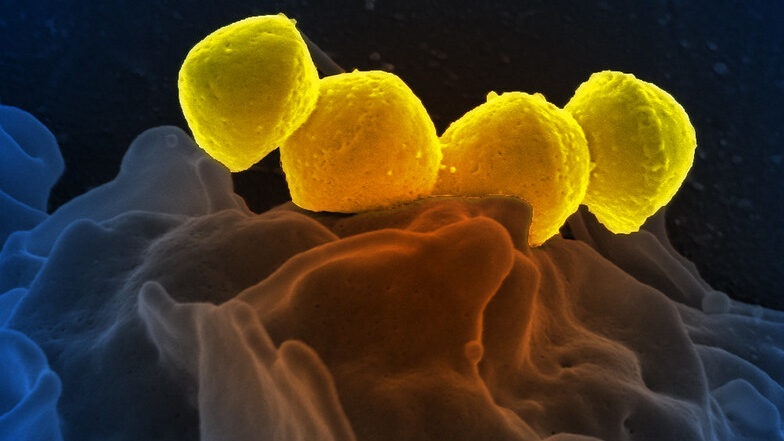

A new study published in Nature Communications reveals a novel approach to mitigating tissue damage caused by Streptococcus pyogenes, the flesh-eating bacterium responsible for severe infections such as necrotising fasciitis. The research highlights how disrupting bacterial metabolism can help the body better tolerate infection and heal more effectively.

The study was led by Wei Xu, PhD, an assistant professor of biomedical sciences at the Marshall University Joan C. Edwards School of Medicine, and colleagues at Washington University School of Medicine and Central China Normal University. The team discovered that S. pyogenes manipulates the body’s immune response through its aerobic mixed-acid fermentation process, which produces metabolic byproducts, such as acetate and formate, that impair immune cell function, delay bacterial clearance and slow wound healing.

By inhibiting this bacterial metabolic pathway with a pyruvate dehydrogenase inhibitor, the team successfully reduced tissue damage in a mouse model of necrotising skin infection. These findings suggest that reprogramming bacterial metabolism could serve as a novel therapeutic approach, not only to improve host tolerance but also as a potential adjuvant therapy alongside antibiotics. This strategy could enhance the effectiveness of existing treatments, particularly in severe infections where antibiotic resistance or excessive inflammation worsens patient outcomes.

“This study sheds light on how bacterial metabolism influences the immune system,” Xu said. “By understanding these interactions, we can develop new treatment strategies that protect tissues, enhance antibiotic efficacy and improve patient outcomes.”

Source: Marshall University Joan C. Edwards School of Medicine